The fabric called denim – Weave

As a follow-up to our article about the most common used twills for weaving denim, today, we will look into the technical side of the weave.

We will start with a small repetition of last weeks’ article. The warp thread and weft thread are interlaced at a 90-degree angle to form the denim fabric. The strong and durable fabric that will emerge is called a twill. We mentioned three different twills that are used to form denim fabric, and how those different twills determine the quality and the look of the fabric. The durability and the weight of a fabric is also influenced by the weave, and this is exactly what we will be looking into.

Three fundamental types of fabric weaves are 3×1, 2×1, and 1×1. Denim is mostly woven as a 3×1 or a 2×1 twill. In a twill weave the warp thread passes two or more times under the weft thread before it will cross one time over. The next warp thread will cross one time over the weft thread before it will pass two or more times under. Shifting the warp thread at every step creates the diagonal line (called wale) that is characteristic for a twill weave. Another characteristic of a twill weave is that the front and the back of the fabric have a different color. In case of a pair of jeans this means indigo versus cotton colored.

The 1×1 construction is used for plenty of other fabrics that are probably hanging in your closet. For the average denim head, chambray and canvas are the most recognizable examples of plain weaves. Now, we will examine the three different types of weaves, starting with the one most commonly used for constructing a pair of jeans.

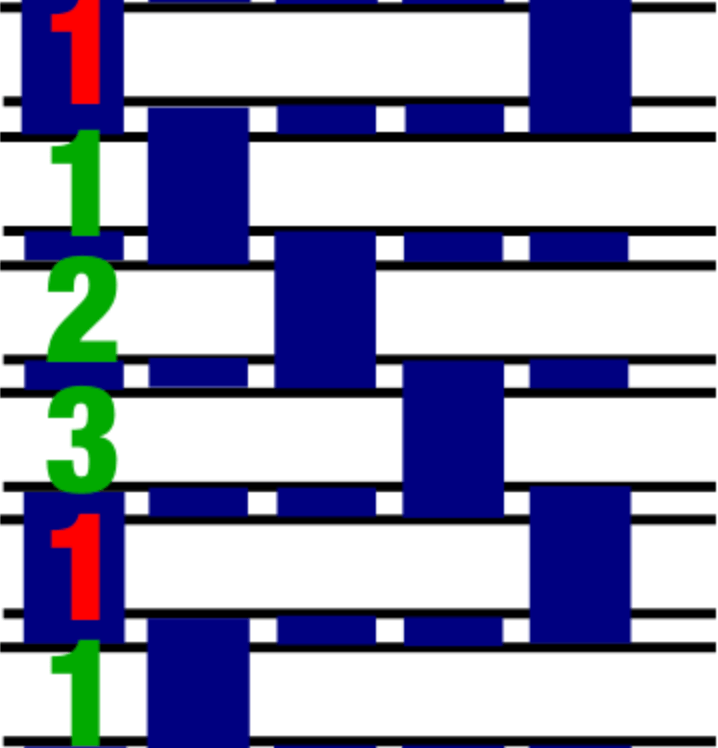

3×1

Selvedge denim is traditionally woven as a 3×1 twill and this is still the most commonly used type of construction. Generally, all jeans made of a fabric heavier than 10.5 oz. are made of a 3×1 twill fabric. The numbers 3 and 1 refer to the number of warp threads per weft thread. The warp crosses three times under the weft, one time over, then again three times under, and so on.

3×1 twill – Photo courtesy of Blue Roots Official.

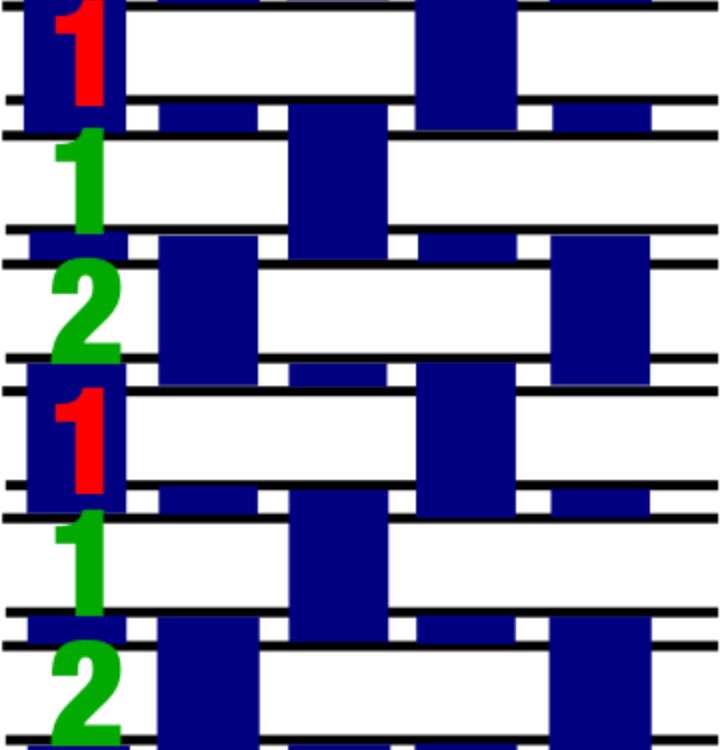

2×1

2×1 twill is woven the same way as a 3×1 fabric but with 2 warp threads per weft thread. Lighter fabrics, weighing less than 10.5 oz. per square yard, are mostly made of a 2×1 fabric. The construction will result in a lighter and more breathable fabric, and is therefore perfectly suitable for hot summer days. While a 2×1 fabric is strong and durable, it can’t compete with a 3×1 fabric.

2×1 twill – Photo courtesy of Blue Roots Official.

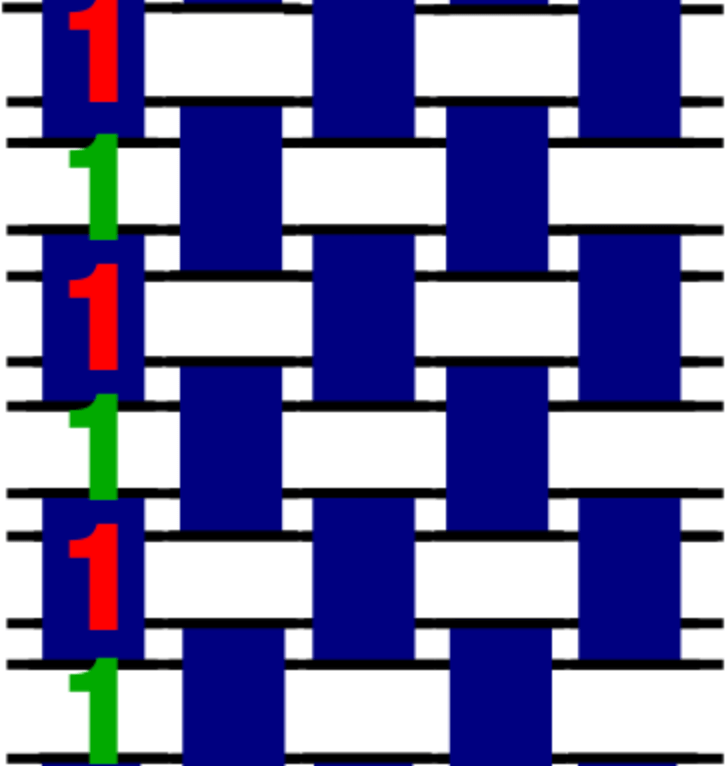

1×1

1×1 also known as a plain weave, is the simplest form of weaving a fabric. The warp thread crosses the weft threads by going under one, then over the next one, under the next one, over, etc. The next warp thread, firstly goes over the weft threads that its neighbor went under, and so on. The emerged pattern will result in a simple crisscross fabric.

In contrast to a twill fabric, both sides of a 1×1 fabric look the same. Examples of popular plain weaves in the denim scenes are cotton and chambray.

Plain weave – Photo courtesy of Blue Roots Official.

As mentioned, the type of twill is determining many aspects of the fabric such as the weight of the fabric. For many guys the weight of the fabric is one of the key factors when they consider buying a new pair of jeans. Next week, we will focus on the weight of the fabric, which can also be roughly divided into three different categories.

Share

Share

Tweet

Tweet