Interview with Kishimoto, managing director of Japan Blue, about the spinning and weaving process

Japan Blue is one of those Japanese brands always trying to innovate their collection, by combining vintage inspirational pieces, with new innovative production processes. Every year, they successfully present another impressive collection, all designed, developed and created in Okayama, Japan. Over the years, Japan Blue grew from the little brother of Momotaro Jeans to one of the most popular denim brands, all under the supervision of mister Hiroki Kishimoto.

Last week we spoke with Kishimoto about the use of cotton at Japan Blue. We talked about the different types of cotton, their characteristics, and origins. In a brief conversation, he explained lots of facts about cotton you might find interesting. So, if you missed it, hit this link, and read our interview about cotton.

Today, Kishimoto cleared his agenda again to speak with Robin Denim about another essential step in the production process of a pair of jeans. Today we will talk about the spinning and weaving process of cotton. What steps are needed to be taken to transform the fluffy cotton bowl in indigo dyed yarns? Kishimoto will explain it all. And, if you still have questions about spinning, weaving or indigo, after reading this article? Send us an email (or DM on Instagram), and we will fire your question to Kishimoto!

Robin Denim: Last week we were talking about cotton. What are the steps that need to be taken before it can be processed into yarns?

Kishimoto: Before we will start processing the cotton, we first check the condition of the fibers. The most important checkpoints are the fiber length, the feeling, and the oil content. We need to check those characteristics to determine the possibilities of the cotton.

Photo courtesy of Japan Blue Jeans.

Robin Denim: Last week you explained why the fiber length and the feel of cotton are essential, but why is the oil content important?

Kishimoto: Just like the fiber length, the oil content of the cotton is determining the eventual fabric and the jeans that can be produced with the cotton. When the cotton contains much oil, the final fabric will have a very and silky feel. Does the cotton contains less oil, the denim will be dry. Both types are very useful for making denim, but, the result will be very different.

Robin Denim: When you are satisfied with the quality of the cotton, the cotton needs to be spun into yarns. Can you please describe the spinning process?

Kishimoto: We receive the cotton in stiffy packed bales, so the first thing we need to do is separating the cotton. When this part is done, we will remove the refuse like leaves, sand, and dust, to clean the cotton. Once the cotton is free of trash, we need to align the cotton, which we will do in four up to six steps. When the cotton is aligned, we will start the spinning process. In three spins, we will change the cotton lint into yarns, ready to be indigo dyed.

During the spinning process, we cherish the character of the cotton because it is determining the eventual appearance of the fabric. Important influences for the character of the fabric are the spinning times and the slub shape.

Photo courtesy of Japan Blue Jeans.

Robin Denim: Where does the spinning process take place? Is Japan Blue overseeing this whole process?

Kishimoto: The process I explained above, takes place at a spinning company in Japan. We are in close contact with agents of the company, and we order samples of many different types of yarns. On the first eye, the yarns look similar, but, when we take a closer look, the characteristics of each yarn is different to another. When we are satisfied with the samples, we order a bulk production, enough to start weaving the fabric.

Robin Denim: Now that the yarns are finished, it is time for the most exciting part of the entire process, namely: Indigo dyeing. What type of indigo do you use? And what method?

Kishimoto: Mostly we use 100% pure indigo to achieve the deepest blue indigo color. Sometimes we mix the indigo with sulfur because it will fade differently and interesting. We use the rope dye method to dye the yarns, because this will result in incredibly deep blue fabric, and it fades extraordinarily.

Another option is hand dyeing the yarns which we call ‘Kase zome’ in Japan. It is also possible to dye mechanically, named cheese dyeing. We use this method for dyeing some of our shirts.

Photo courtesy of Japan Blue Jeans.

Robin Denim: So, for most of the fabric you use the Rope Dye method. Can you please describe this process?

Kishimoto: We order the indigo from a Japanese chemical company. This company produces very high-quality indigo in their factory in China. When we receive the indigo, it is powder, so we need to change it into a liquid. We add water to the powder, plus some additives for an elevated pH, a condition known as alkalinity.

When the indigo dye is finished, we are ready to Rope Dye the yarns in our factory. In our facility, we have 12 baths that we use for rope dyeing the yarns.

First, we twist the yarns into ropes, and then briefly dip them in the indigo bath. Then, the yarn will get in touch with oxygen, this stage is called oxidation, which turns to yarns from green into blue, and helps to indigo fix to the yarn. This process needs to be repeated until we are satisfied with the deep blue indigo color. Because of the short dyeing period, the core of the yarn will stay white, resulting in a faster-fading fabric.

Robin Denim: Now the yarns are indigo dyed, they are ready to be woven. Can you please describe the weaving process?

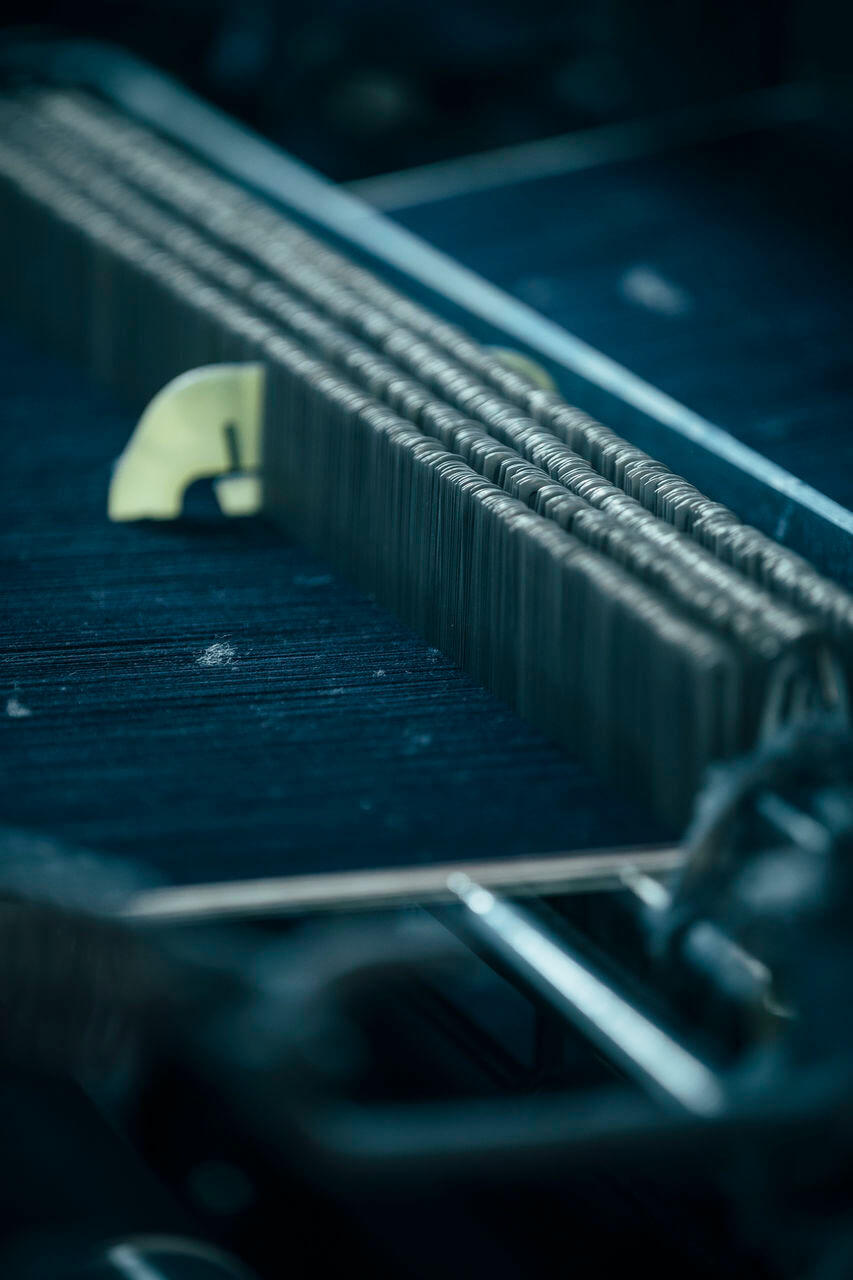

Kishimoto: As you might already know, we use old vintage shuttle looms to create high-quality selvedge denim. Although modern looms are quicker and more efficient, they cannot compete with the high quality and character achieved by vintage shuttle looms. Each shuttle loom allows us to weave 1 meter of fabric every 15 minutes. But, before we can even start weaving, we have already passed a period of preparation (spinning and dyeing) which takes up to 2 months, so the whole process is very time-consuming.

The first step to weave the fabric is setting the warp and the weft yarn into the shuttle loom. Before we start weaving the warp and the weft, we need to connect the yarn ends together to avoid the shuttle looms to run out of yarns. If we want to produce the same fabric as we did the last time, we will just run the shuttle loom. But, if we’re going to make another fabric, we need to adjust the tension and speed and do a test run before we start producing. Once we are satisfied with the test fabric, we begin producing the fabric.

Photo courtesy of Japan Blue Jeans.

Robin Denim: Where does the weaving process of Japan Blue fabrics take place? Are all fabrics made in your factories? How many looms are used for making it?

Kishimoto: Not all fabrics we use for our collections are made in our factory. It is just impossible because we need more looms than we have. At the moment, we have nine looms running day and night to produce as much denim fabric as possible. But, to make enough fabric for our collections, we need at least 15 to 20 looms. That’s why we are working together with other big factories in Japan, having up to 80 looms up and running. Of course, we carefully select our partners, because they have to meet our expectations.

Robin Denim: Thanks for explaining the whole process! One last question: What is, in your opinion, the most special fabric that Japan Blue has ever created?

Kishimoto: The 13.5 oz. Cote d’Ivoire cotton selvage denim is, in my opinion, the most special denim we have ever created. Everything about this fabric is natural, the feeling is excellent, and the eventual fades are unequaled. With 13.5 oz. it is very comfortable to wear, and the weight is perfect to wear in all seasons. As far as I know, we are the only brand using 100% Cote d’Ivoire cotton, making this fabric even more special.

Share

Share

Tweet

Tweet