Soorty – The World of Denim

This is likely the first time you have read about Soorty, at least here on Robin Denim. By providing fabrics and garments directly to brands we buy from, their main focus isn’t the end-consumer, so it’s not strange if you haven’t heard their name before.

But, what if we told you that every single one of you probably has pieces hanging in your closet whose fabrics have been woven by Soorty?

Soorty is Pakistan’s largest vertically integrated denim manufacturer and one of the fastest growing denim companies in Asia. Established in 1983, they are heavily focused on research and development. Soorty is providing jobs to almost 30,000 people and they have the facilities and knowledge to manage every single stage of jeans production in-house.

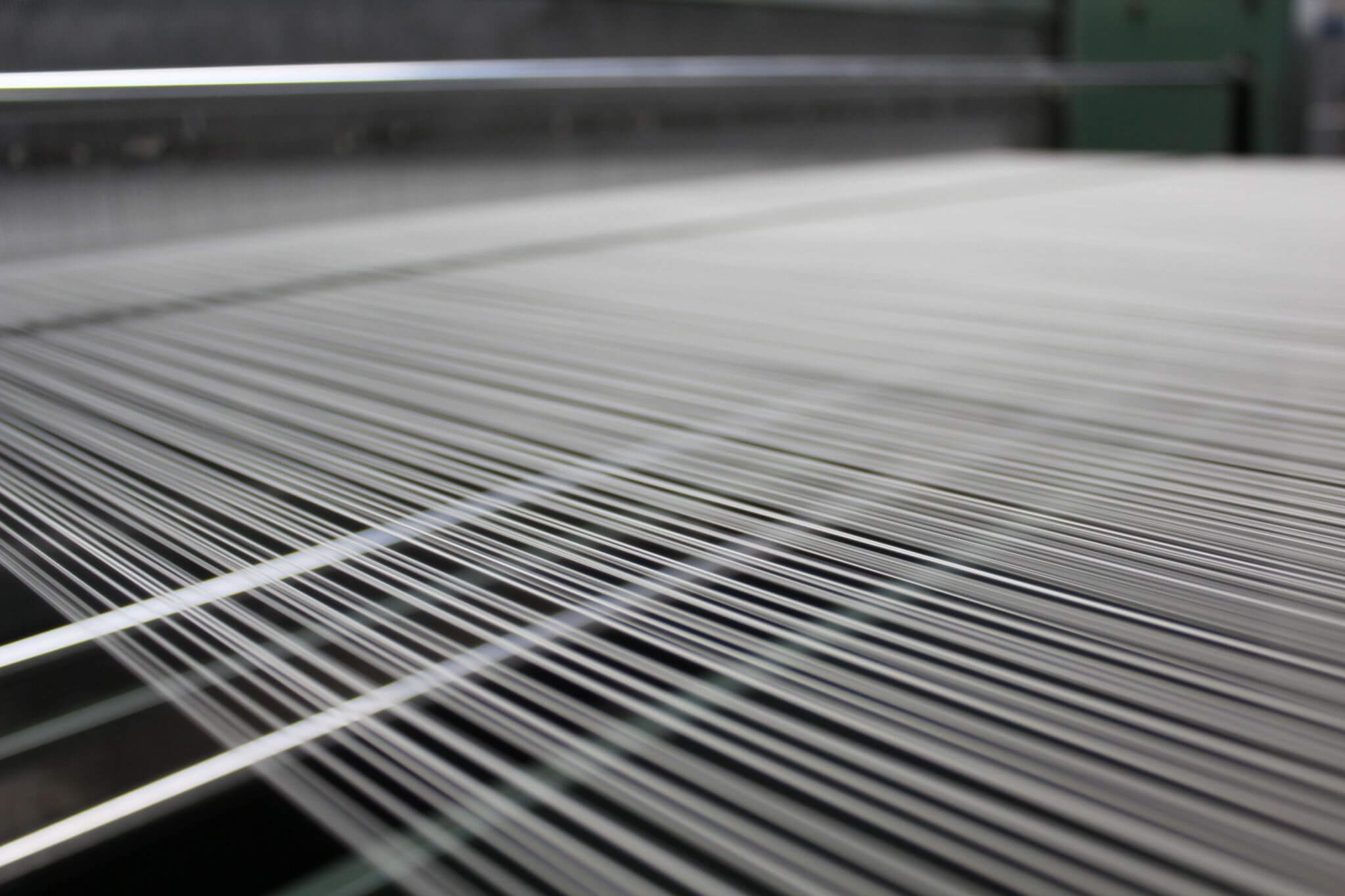

Photo courtesy of Soorty.

Photo courtesy of Soorty.

Making denim

In 2007 Soorty expanded the company with a denim division and fast forward a few years, they now have a capacity of weaving 70 million meters of fabric per year. Of this dizzying quantity of fabric, 40 million denim pieces will be called to life each year, while the rest is available for export.

As Soorty is a vertically integrated manufacturer, they are able to manage the whole production process, from spinning yarns to finishing garments. Having the ability to do this, combined with in-house knowledge and expertise, is resulting in an incredibly fast lead time for new developments (also known as ‘speed to market’).

For a leading company like Soorty, their awareness of trends in fashion and industry is a high priority. As a result, there is an extensive and seasoned Research and Development (R&D) team which co-ordinates new collections and develops new ideas (from yarns to washing techniques) on a continuous basis.

Next to the R&D team, Soorty has an in-house Product Development (PD) team, taking care of ongoing technical innovations. By experimenting with different kinds of compositions, innovations and technologies, the PD team is always searching for developments and innovations that add value or uniqueness to their product. Soorty always brings something new to its fabric collection, which can sometimes be unconventional, but is always rich in values!

Photo courtesy of Soorty.

Photo courtesy of Soorty.

Mission and beliefs

Deeply rooted in Soorty’s identity is the desire to deliver value for money and to bring the right product to market at the right time. As an innovative and constantly evolving product development leader, they are always ready to experiment with new approaches to enhance their offering.

Contrary to popular beliefs about manufacturing in Asia, Soorty is taking good care of their employees, their local communities and cities. Moreover, they are about to open a hypermodern production facility in Pakistan, which will be more modern, environment and employee-friendly than the average manufacturing facility in Europe.

Perhaps their most important mission, however, is their urge in making the world a better place.

Photo courtesy of Koen Kuik.

Photo courtesy of Koen Kuik.

Sustainability

Sustainability is one of the top priorities on Soorty’s agenda. Every part of the company is arranged to be as responsible as possible, in an effort to make a difference in an already polluted fashion industry. As a part of Soorty’s philosophy and continuous improvements, they have re-invented the way of finishing denim. We will spare you all the technical details, but the results of this are beyond impressive. They have managed to innovate a certain type of fabric finishing that decreases the use of water by 98%; Energy consumption (-97%) and CO2 emissions (-99%) are also dramatically reduced.

Another sustainable solution of Soorty, is their ‘recycling plant’. Developed to find new uses to what was once considered waste, Soorty’s state of the art recycling facility can repurpose both post consumer and post industrial waste. Post industrial waste is the waste they generate themselves during production and the numbers are quite impressive considering the production capacity. For example, reusing the cutting table waste, they save 7,5 tons of fiber per month. The second step is the recycling of post consumer waste. They have teamed up with I:COLLECT – a global solution provider for reused and recycled garments – to collect garments that were meant to go to landfills. Materials including post consumer and post industrial waste will be recycled into fibers which can be processed into new denim yarns.

Photo courtesy of Soorty.

Photo courtesy of Soorty.

In a polluted industry that is heavily driven by financial gain, Soorty have kick-started an impressive and steadfast revolution in order to change what is considered to be the norm. The more we read about Soorty, the more impressed we were by their expertise, knowledge, vision and ‘sustainable mission’. Soorty’s huge production capacity and investment in industry developments, combined with their vision on sustainability and environmental impact, is truly making a difference.

Head over to Soorty’s website to learn more about the company or follow them on Instagram to get in touch!

Share

Share

Tweet

Tweet