Interview with Becky and Huw, founders of Paynter Jacket Co.

By @jasonvanpul

Sometimes something grabs your attention because it clicks. Everything seems to make sense and the story behind it is so interesting that you like to learn more. I had this click a little while ago when I ran into this new brand called Paynter Jacket Co. The people behind it are Huw Thomas and Becky Okell. Over the past few weeks we started a conversation through a series of messages. As I learned more about them and what kept them busy I realized it was about time to get to know them better.

Huw and Becky are the founders of Paynter Jacket Co. A small business that produces limited edition chore jackets. They will release as little as three batches a year which they sell online. Becky studied textiles at Central St. Martins in London and went on to work at the British Fashion Council, Nike and It’s Nice That. Huw went to University in South Wales where he grew up. He dropped out in his second year and worked in marketing before eventually joining Hiut Denim and The Do Lectures where he (still) works in product, marketing and sales.

Jason: So Huw, let’s continue with you working at Hiut Denim. How is working for this amazing denim brand like?

Huw: Working at Hiut Denim is a dream come true. I get to work very close with the founders, two world class brand builders, helping them build the Hiut Denim brand. There I help develop new products, search the best mills all over the world for the best and most interesting denims, and tell their stories to our community. I love my job, and I’m given a lot of responsibility which you would never get at another brand. After working at Hiut for nearly four years, I’ve learned that it comes down to two things: make a great product and tell a great story. Focus on making the best, not the most. Focus on one product, not many products. Doing one thing, and do it well.

Working in the same building as our factory has also opened my eyes to how a product is made. You see the whole process every day, from beginning to end, and it never gets old. You get the chance to learn from the ‘Grand Masters’ how a jean is made, what every machine does, and how different fabrics change during the making process. You can get super geeky on this stuff. It was from everything that they taught me that I learned how to sew and make my own jackets out of scrap denim left over from the cutting table.

Jason: How is it to combine working for two brands? Do they compliment each other in terms of the creative process or in any other way?

Huw: Working for Hiut and starting Paynter is very simple. I focus on jeans during the day and jackets at night. Everything I learn from doing one compliments the other.

Jason: Did working in the denim industry already mean it was easy to find production for your jackets?

Huw: To be honest, not really. Finding a factory isn’t easy at all. Most factories we spoke to make one style of product, and then they outsource their making. We talked to a lot before finding the right maker. Once we found them, we got on a plane and visited. They’re based just outside Porto which means it’s close enough to go over, meet the team and see every process from start to finish. Working in the industry helped us know what questions were important to ask suppliers, but it’s not until you’re face to face with the makers and see every part of the process from thread to dye-house when you’ll really start to know what you’re doing.

Jason: You produce limited edition jackets three times a year. Why did you decide on this strategy?

Huw: There are a few reasons why we sell in batches, rather than being available to buy any day. Making to order means there’s a lot less waste than usual. 175 billion garments are made every year. 50 billion never make it to the shop and go straight to landfill, another 50 billion go to landfill after not being sold. There’s enough out there, so we didn’t want to make something people wouldn’t cherish. The drop model is pretty normal in hyped up streetwear, but not in an industry that cares about quality. We wanted to build a business that was totally transparent and interesting from every angle, from product to the business model itself.

Jason: Where does your inspiration for a chore jacket come from and why did you decide to build a business around it?

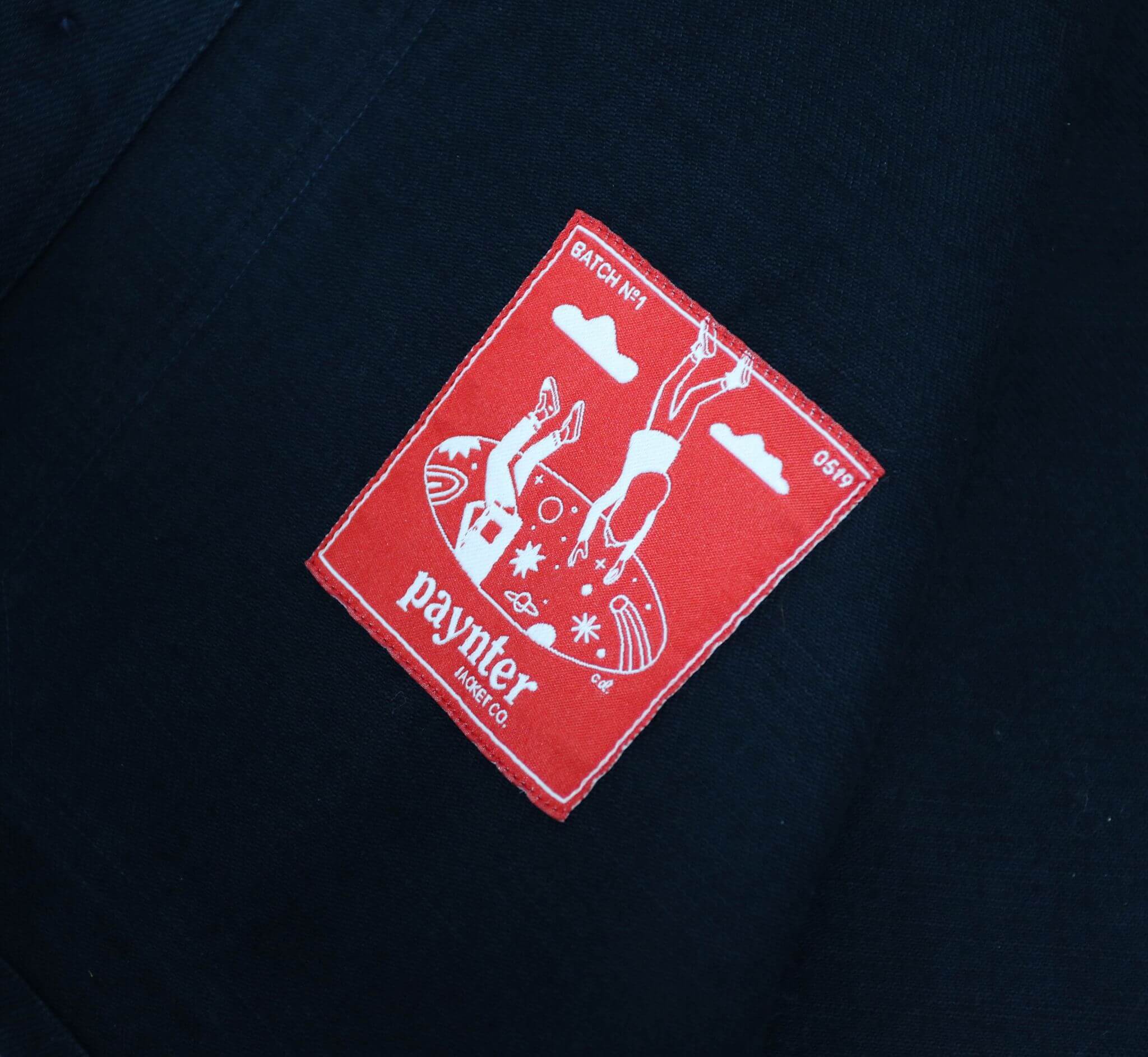

Becky: We take iconic jackets and deconstruct them, then rebuild them using the best materials from around the world. Jackets are the perfect canvas to have fun, whether that’s through details on the inside or choosing a stunning fabric that’s made to last. Another great thing about jackets is that they’re made to be seen, worn on the outside, and intended to be worn and worn again. They’re timeless rather than seasonal. For Batch No. 1 we’re remaking the iconic French chore jacket. It’s a jacket that can be worn day in, day out. It’s practical but it’s also great for the city. We’ve added extra details like the card pocket inside and limited edition illustrations on woven labels, only for the first 300 jackets that will be launching on May 11th. They will be available for purchase for 1 week!

Jason: How specific are you when sourcing materials?

Becky: Finding the right materials to suit the jacket we’re making is what takes the most time. During the making of Batch No. 1, we learned that almost every other chore jacket sold in London is made using one of two fabrics, who’s origin isn’t known. That didn’t sit right so we set out to find a fabric we could trace to the raw material. We chose a 100% cotton Reverse Bull Denim, that’s made in Berto, a mill just outside Venice in Italy. It’s hard as nails, but soft AF. The fabric has a uniform appearance on the outside and an interesting stubby, lined texture inside. The 3 x 1 weave means it’s super strong, and its garment dyed to the exact colours we were looking for. The buttons came next. We didn’t want to use plastic, so we managed to find a button company (Courtney & Co) who have made buttons for 150+ years. Although our buttons look a bit like plastic, they’re actually made from nuts, so they’re biodegradable and beautiful. Bonus.

Jason: Can you tell us about the process of design? Where does the inspiration come from?

Becky: We have a list of iconic jackets we will make. It’s just about deciding which order we make them in. We’ll often start with a vintage piece, then tweak it to suit the fit we’re looking for. Once a pattern and prototype is made, we’ll wear it most days for a few months to see how it feels. That’s when you really know what changes need to be made. It’s quite normal in the outdoors market to test this much, but not in fashion, it’s too quick. We tend to go through five samples before getting to the final piece we’re happy with since the process includes every detail from the inside out.

Jason: Guys, I enjoyed this interview very much. There’s one last question I have for you. In what way do your personal preferences influence the brand?

Becky: In every way! We both love making. Huw made jackets with scraps of denim way before we started Paynter. We’re both so nosey. We love learning how factories work and about every process from raw materials to dying. On the business side of things, we wanted to focus on one product so we can make a f**king good one! It means we’re very happy running a small but interesting business. No major growth plans here.

Share

Share

Tweet

Tweet