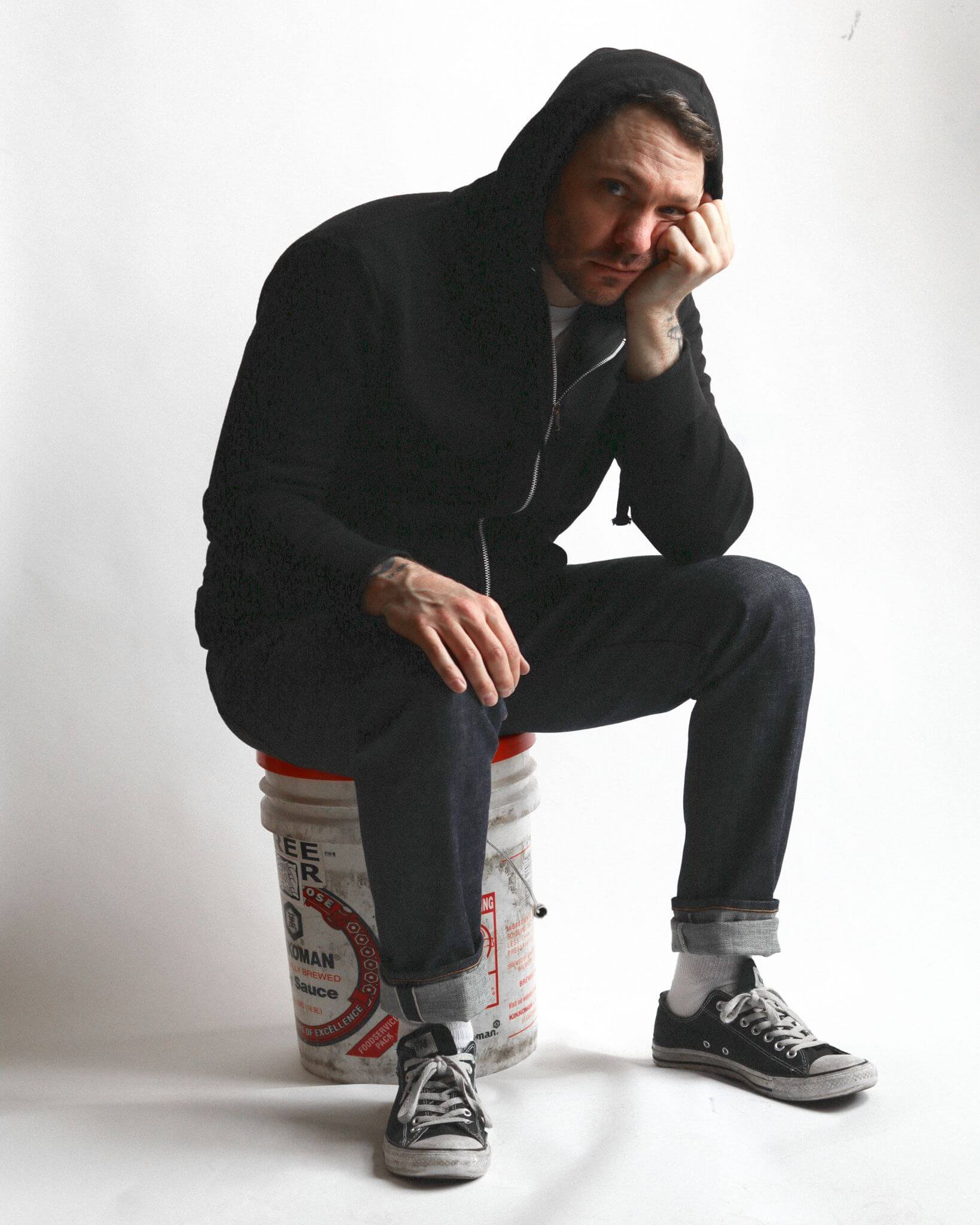

Interview with Mike Ranta, founder and owner of Encampment Company

Encampment Company was started in 2015 by Mike Ranta in Wyoming, USA. Mike – who hasn’t been a denimhead his whole life and neither has a background in fashion or design – was hopping freight trains and started a brand because he likes clothes. It took him almost 5 years to understand selvedge denim, to source and repair his machinery and to practice his skills before he was able to offer his first pair of Selvedge jeans – something he didn’t plan when he started the brand!

We stumbled upon Encampment on Instagram, and we were impressed by the clean designs, cool details and good looking fabrics. After taking a closer look at the brand’s website, we reached out to Mike to learn more and share his interesting story on Robin Denim.

Make sure to check out Encampment’s website to learn more about the one-man brand that is making high quality garments by just one pair of hands on American soil.

Robin Denim (RD): Hi Mike, can you please start by introducing yourself?

Mike Ranta (MR): Hey I’m Mike, I started the Encampment Company with a single sewing machine in a cabin in Wyoming. Now I have more sewing machines and less cabin.

RD: Before you started the brand, you were on a freight train, right? What made you decide to start a denim brand and what was the original intention with Encampment?

MR: When I was in my 20’s I sold everything I owned and started riding freight trains around the US. When I was in Montana one day I met a guy who made his own vest and it gave me the idea to do the same for myself. It all started to spiral out of control that winter when I got to my cabin back in Wyoming. That’s when I started stockpiling and repairing old sewing machines, which was a two year project before the brand ever even launched. To be honest I didn’t know anything about the denim industry when I started the company and I didn’t know what selvedge denim was. When I started looking into it I saw the quality and the craftsmanship and it seemed like a really natural fit.

RD: You started the brand in 2015. What have been some of the highlights for you? Has your approach to being a denim brand changed over the last five years?

MR: I started by only wanting to make jackets. When I launched, I only had denim and waxed canvas jackets and I had zero understanding of what I was really doing, but I was getting a lot of great feedback. I recently started to make jeans and that has been a huge highlight in my work.

I didn’t want to jump into selvedge jeans right away. To make really nice jeans you’ve got to have your act together. I have always taught myself everything from the ground-up and in the beginning I just wasn’t good enough as a craftsman. It has taken me five years of continuous sewing to arrive at the jeans I’m starting to produce, and I know the quality shows. With that experience under my belt I’m moving back into the denim world a little bit more and it has been really satisfying.

RD: Can you tell us more about your current location in Phoenix, Arizona, and the advantages or disadvantages of designing, sourcing and producing there?

MR: Arizona doesn’t have any particular advantages. It’s better for sourcing fabrics than living in Wyoming where absolutely everything had to be shipped and took over a week in transit. But really, I’m just happier in Arizona than in Wyoming. I was living in an ice-cold warehouse there with this landlord named ‘Bull’ who would blow up toilettes with dynamite behind my shop. I make all of my clothes in-house so the only hard part is getting the fabric to me from Japan.

RD: What are the most important values of Encampment and why?

MR: The values of Encampment are my personal values. I treat people like people, I’m proud of what I make in my shop, and I’m deeply obsessed with quality. I’m making clothes specifically for you and I want you to be happy with what you get and if possible I want you to get something beyond your expectations. If you just want a really nice pair of jeans, I’ve got that. If you want to look closer and see that I tie the stitching on the leather patch by hand so it looks as clean as possible, I’ve got those sort of details too.

RD: What are the most important influences for Encampment’s collections? Where does the inspiration originate?

MR: I was always inspired by 1950s Americana images, I grew up looking at photographs from Saul Leiter and listening to Motown and my brain sort of lives there in that era. Things still had value back then, when you bought a jacket or jeans they were yours. You didn’t own as much and jeans and jackets from that era are still sought after.

When I was basically homeless and riding trains I was in this abandoned hotel in the Midwest and I pulled a pair of selvedge 501s out of a pile of trash and dirt. They were covered in paint and just totally shredded, whoever owned them really wore them until they couldn’t be worn anymore. Those jeans still had value when I pulled them out of the trash in almost unwearable condition. That’s the feeling I try to sew into everything.

I sold the 501s on eBay so I could buy new boots…

RD: You have a relatively small collection. What made you decide to keep it small?

MR: I used to have a bigger selection but it drove me crazy. It’s just me sewing everything and it just isn’t sustainable to design and manufacture so many things. Now I just focus on the things that I really want to make and I’m less crazy.

Part of the reason is that when you churn out new products season after season you get into this new market where you’re constantly looking for new fabrics and new designs. That’s how mid-size and large brands survive, they need to have new products every season. I just didn’t want to play that game as a one-man-brand. I’ll make the things that call to me.

RD: What are the signatures of the brand?

MR: The one thing that sets Encampment apart is me. I’m passionate about making these things, to the point of outright obsession. I wake up in the night thinking about patterns. I have been caught staring at men’s jeans in a way that sends the wrong message. I was banned from a sewing machine wholesaler for arguing with a staff member about how to time machines properly. I have so many sewing machine heads in my shop that I had to store two in the bathroom because I’m out of room.

I really love what I do!

RD: You are solely working with the best Japanese and American made selvedge fabrics. How do you select the fabrics?

MR: Each denim is selected for a specific reason, usually it has a standout quality like it’s slub or finishing, but it also must check every single box. Every material must be the right weight, right weave and the right dye. I will buy a sample of each product from a mill’s inventory and test how they will fade, I always take that into consideration when I’m choosing denim. “How would this look in 1 year? 10 years?”

I always choose fabrics that bring value to the garments I’m making. I put so much work into each pair of jeans and every single jacket, it would only be half the battle to choose second quality fabrics. Part of the reason for selecting Japanese fabrics is I know that Japan has a high standard for how it treats its workers. There are high-quality selvedge denims made in other places that are significantly cheaper, but I don’t know enough about their supply chain and how they treat their workers. Taking that chance just doesn’t sit well with me. Plus, I want to do my part in keeping Japanese mills alive, I don’t want them going the way of Cone Mills White Oak and American Cotton Growers Denim Mill. I’m not chasing the lowest price, and neither are my customers.

RD: What can we expect from Encampment in the near future?

MR: More jeans. Much more jeans. More denim. Much more denim.

Share

Share

Tweet

Tweet