Simply Suzette explains the impact of making denim

We entered the denim industry in 2014 as big fans of the magical blue dye. A few years later, we continued our indigo journey by starting this website in order to provide more in-depth information about our findings. Wandering around in the industry led to being informed about the industry’s state of art, its current blue trends, and getting to know many inspiring people.

One of the inspiring people we met during a denim trade show is Ani Wells a.k.a. Simply Suzette. Ani, born and raised in Toronto, Canada, is running an online platform which bridges the gap between the denim industry and consumers. On the platform, named Simply Suzette, Ani provides her readers with the information they need to make more informed purchases. She goes behind the scenes to bring them the secrets of the industry, focussing on the consequences denim production has on people and our planet.

We are regularly checking in on simplysuzette.com, as we agree with her point of view regarding the issues she raises. The effort Ani is putting in communicating the industry’s sustainable solutions (and needs) is admirable! Thanks Ani for shining your light on some of the industry’s most delicate subjects!

Photo courtesy of Simply Suzette.

Photo courtesy of Simply Suzette.

Denim.

If you are wondering why traditional denim production is so bad for the environment, it generally takes 2000 gallons of water to produce just ONE pair of jeans, not to mention all of the harsh chemicals that go into making them, as well. To whoever is reading this, I am sure you know how amazing our little denim community/industry is and the blue world has worked extremely hard to find solutions to all of our problems. So, let’s dive into why denim production can be harmful, but also take a look at some of the solutions our blue fam has created.

Photo courtesy of Kings of Indigo.

Photo courtesy of Kings of Indigo.

Water.

The amount of water used for manufacturing denim is extremely exhaustive of the earth’s finite resources. And around 1500 gallons of that is just enough to produce enough cotton for 1 pair of jeans. The rest is used in the dyeing and finishing process.

Wastewater is also a major issue with processing denim that comes with the finishing techniques to achieve stonewashed looks. After denim has gone through the washing process, toxic sludge is left and disposed of in unethical and unsustainable ways.

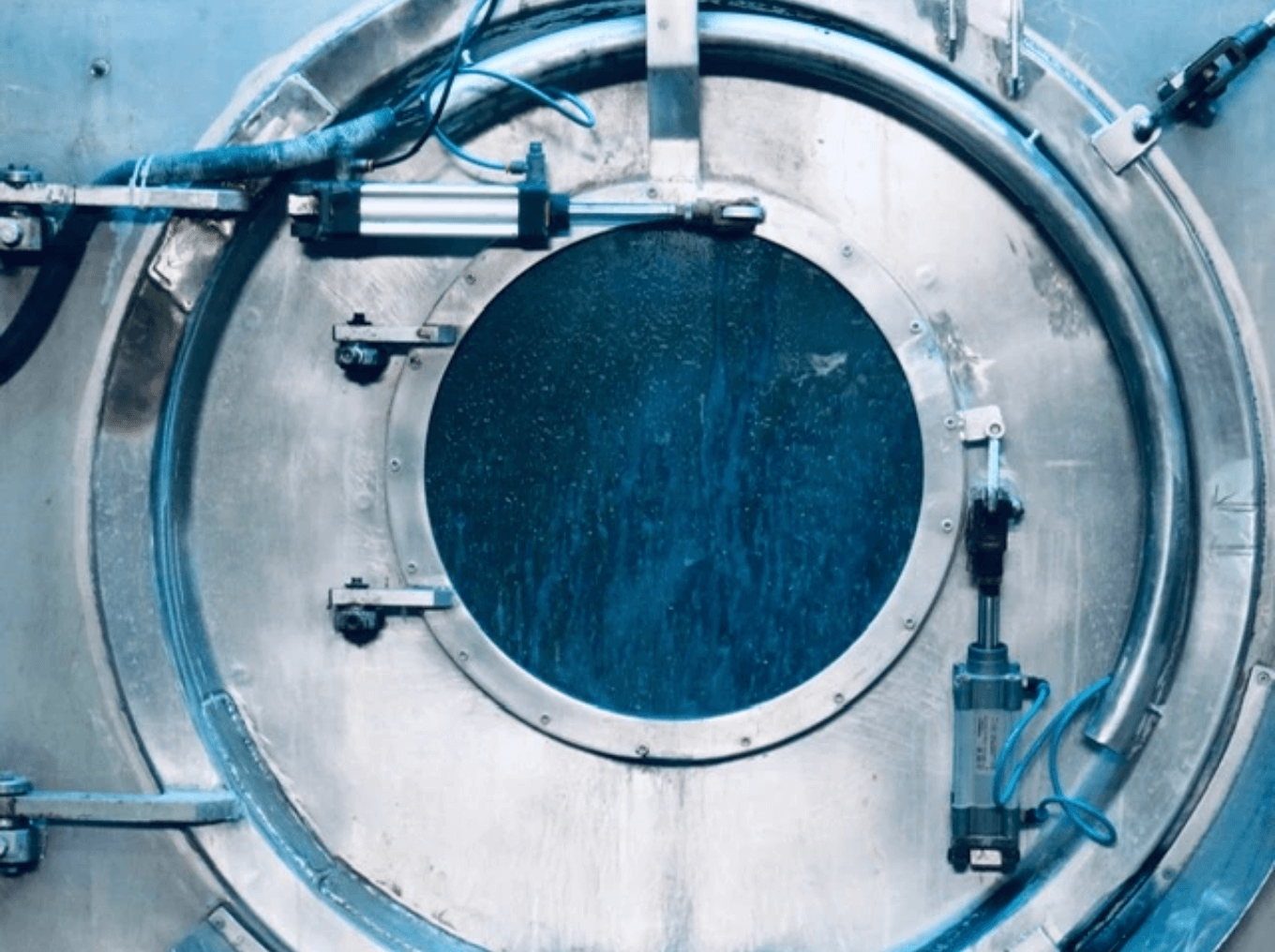

However, there are many solutions that solve our water usage and wastewater disposal problems. Lasers have been proven to virtually eliminate the water needed to achieve whiskering and fading, as well as ozone gas that can be used as a stonewash replacement. Foam dyeing is a newer technology that claims to eliminate all water by using a watery like solution to disperse the dye onto the yarns versus dipping them into indigo boxes. Pretty neat if you ask me!

Water filtration systems can clean the blue water used in the production process and circle it back into the production loop. This allows up to 98% of the water used for washing to be reused over and over. Lastly, the sludge created from washing the jeans can be mixed with cement and turned into bricks!

Photo courtesy of Supima.

Cotton.

Conventional cotton can have a serious carbon footprint and has been denim’s primary fiber of choice since the dawn of its time. But as we learn more about its impacts, mills, and manufacturers are looking to alternatives to reduce denim’s reliance on cotton. But, for now, cotton is still the primary fiber in denim production and with good management, does not have to be so bad for the planet.

Cotton is very pesticide-intensive. Although it is only grown on 2.5% of the world’s agricultural land, it consumes 16% of all the insecticides and 6.8% of all herbicides used worldwide.

These pesticides are then washed out in the soil, and pollute rivers and groundwater. The chemicals used not only get rid of the pests, but they also get rid of the good bacteria needed for healthy soil! This interferes with the ecosystem and reduces the amount of biodiversity significantly.

However, the key sustainability issues with cotton come from poor management practices. Programs like The Better Cotton Initiative, train small farms to grow and harvest their crops in an environmentally friendly way by following certain guidelines:

- Use just the right amount of fertilizers

- Use just the right amount of water for irrigation

- Manage the planting such that water does not pool around the roots

- Control the use of pesticides

More water-efficient fibers that denim mills are blending their cotton with include organic cotton, BCI cotton, hemp, Tencel, REFIBRA™, and recycled cotton.

Photo courtesy of Koen Kuik.

Photo courtesy of Koen Kuik.

Chemicals.

Synthetic indigo has become the norm for producing jeans and natural indigo has become more of an artisanal craft. With synthetic indigo, caustic (bleach) and hydrosulfite (a toxic substance) is needed and creates millions of gallons of wastewater from the dyeing process every year. If this water is not treated before disposal, it is washed away into our beautiful oceans cause detrimental environmental impacts. Pre-reduced indigo is a more sustainable option, but less than 30% of the industry has switched to this.

Bioengineered indigo is one of the coolest new inventions on the scene. Instead of using petroleum and cyanide, bioengineered indigo turns sugar into the indigo blue dye! I have also seen “no-dye” denim that uses the dye from recycled cotton, so no more is needed.

Photo courtesy of Waldemar Brandt.

Photo courtesy of Waldemar Brandt.

Over Consumption / Over Production.

It is no doubt that fashion is one of the most wasteful industries and denim, in particular, is always under attack for being one of the worst offenders. 8% of all greenhouse gas emissions are linked to the manufacturing of garments and unfortunately, garments are being worn 40% less than the previous generation. This leads us to the real problem – overproduction / overconsumption.

30% of what is produced is never actually worn, meaning a lot of the excess that was produced goes straight to the landfill. Some brands will partner with different organizations to donate their unsold goods, but if about 6 BILLION jeans are produced a year, 30% (1.8 billion pairs of jeans) is WAY too high a number and brands need to be analyzing their data to make their supply chain more efficient and minimize waste.

In order to change the outcome of denim production, it needs to start at an individual level. We need to always be in the mindset of “Buy Less, Choose Well, Make it Last,” and ask:

Where was this made?

Who was this made by and what were they paid?

What effect did it’s productions have on this planet?

What will happen to it when I am done with it?

We can change our mindsets and ask the questions, but actually doing something about it is the hardest part. Sustainability is a journey that looks very different for everyone. It can start with taking your old pair of worn-out jeans to a donation center or buying a good quality pair of Japanese selvedge that will last you years instead of a $20.00 pair that will barely last a season.

For me, it started with education and that’s why I started Simply Suzette! I hope you learned something new today and could geek out over denim and sustainability with me. Thanks to Robin for having me on the blog and stay diligent friends!

Photo courtesy of CourseHorse.

Photo courtesy of CourseHorse.

Share

Share

Tweet

Tweet