How Kojima Became the Epicenter of Japanese denim

Japanese denim has a reputation of being the best in the world, and for good reason. While it doesn’t have nearly as long of a history with denim production as other countries, Japanese denim has become known for its unparalleled quality and traditional production processes. By strictly using materials of the highest quality and by continuously innovating the manufacturing of denim – all with an incredible eye for detail – Japan did with denim what Japan does best; elevating a product to the next level, and beyond.

Taking a closer look at where denim related activities are clustered in Japan, one prefecture stands out above all others. Sure, high quality denim is made all over Japan, but in Okayama prefecture, and Kojima to be specific, there are more brands, mills and denim stores than most anywhere else in Japan.

Over the years, the majority of Japanese denim brands and mills have moved their production and offices to Kojima. But why? And how, does a small village far away from the capital of Tokyo, become the epicenter of the Japanese denim industry?

To give an answer to these questions, we reached out to Yoshi Yakushiji, founder and owner of Star Gold, an agency that represents several major Japanese denim brands in the overseas market. By being responsible for the overseas sales and marketing activities for brands like Big John, Samurai Jeans and Studio D’Artisan, Yoshi became an expert with an impeccable reputation and an in-depth knowledge of the industry. We met Yoshi-san several years ago at a denim trade show in Berlin and we have kept in close contact ever since. Arigatō Yoshi, for being so kind to provide us with some in-depth and hard-to-find knowledge about the history of denim in Kojima.

The Island of Kojima

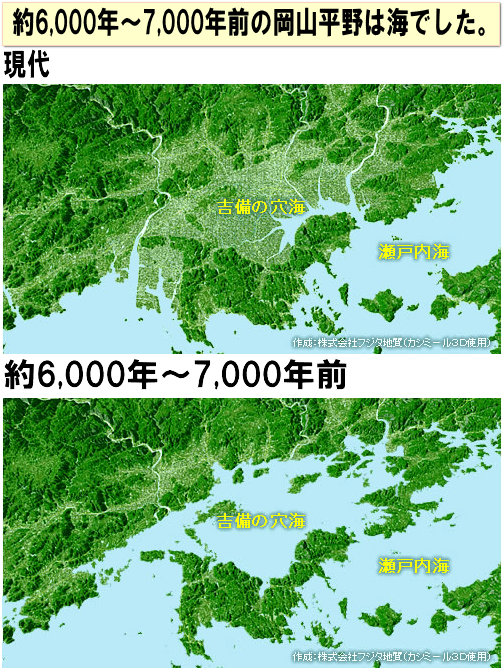

To understand why – and how – Kojima evolved into a Japanese denim Mecca, we need to go back to the 1500s. Until that time, Kojima was just one of Japan’s many islands, with no distinct expertise in the garment industry. During the 1500s, the island was going through a period of increased population growth. Alongside this, the demand for food rose and soon a shortage of food threatened the people on Kojima. There simply wasn’t enough land to grow rice and other foods needed to feed all the people of the island.

In order to meet the increasing demand for food, the government decided to start reclaiming land in the Kojima area. The ocean between Kojima and the mainland wasn’t that deep, and included many smaller islands, so it was an obvious decision to reclaim this land. After the reclamation, the new district between Kojima and the mainland of Japan was 5500 hectares richer (which is around 7,700 soccer fields). The reclaimed land brought what the area needed; more space for agriculture and more housing. Not only solving the problem of the fast-growing population and associated rising demands for produce, it also made the area future-proof – it provided space to grow and develop.

But, once the local farmers tried to grow rice another problem arose, the reclaimed land was too salty to grow important foods such as rice. This unforeseen challenge brought a new mission for the government and farmers – they had to find a solution and purpose for the reclaimed land which would help meet the growing demand of food and requirement for jobs.

How Kojima became a Manufacturing District

Looking for a much needed solution, it was realized that cotton doesn’t necessarily need fresh water to grow. In contrast to rice, cotton could grow in a salty soil, providing the whole area with a new perspective and opportunity for future growth. It wasn’t exactly the solution the people were hoping for, but time told it to be an even better solution than anyone expected.

Alongside the cotton plantations, a whole new industry arose from the earth for the people of Kojima. People decided to stay in the area, or even move to Kojima, in order to help build a foundation for this new industry. Part of the harvested cotton was sold, giving the local economy a boost, but most of the cotton was processed right in Kojima.

When local artisans started to make canvas fabric, for which Kojima is still famous for, the ball really started rolling. It didn’t take long before Kojima could take care of the entire manufacturing process and major companies opened their doors in the area. They started using the canvas fabrics to make workwear and school uniforms that thereafter have been worn by kids all over Japan.

Kojima flourished like never before and instead of a threatening food shortage, the growing industry provided jobs to anyone and everyone who wanted to be a part of it.

Momotaro Jeans factory. Photo courtesy of Koen Kuik.

Momotaro Jeans factory. Photo courtesy of Koen Kuik.

A New Trend Hits Japan

The same as with every other industry, manufacturing processes in Kojima naturally needed to evolve. After the Second World War, technology improved significantly, with polyester and nylon fabrics being introduced to the market. While Kojima had become famous for cotton fabrics and manufacturing school uniforms, this wasn’t enough and it needed to look forward towards new trends and needs, in order to continue to grow and develop.

A new wave came in the 1950s when American culture and what we now refer to as vintage clothing became popular in Japan. The obsession with and popularity of this new movement was exactly what Kojima needed, with Japanese youths becoming obsessed with American ‘blue gold’ (denim) and all that it stood for. With icons like Elvis Presley and James Dean wearing jeans, denim became immensely popular in Japan. Japanese citizens would befriend US servicemen or visit the ‘PX’ store on American bases in order to acquire a pair of Levi’s, so that they had the authentic article to wear on the streets of Osaka or Tokyo. But what the Japanese also realized was the commonalities of American denim and Kojima cotton – denim was a heavy weight and hard wearing fabric, just like what had been manufactured in Kojima years prior.

Collect Mills. Photo courtesy of Koen Kuik.

Collect Mills. Photo courtesy of Koen Kuik.

The Birthplace of Japanese Denim

Just a few years after American style became a hot fashion trend in Japan, the first Japanese denim brands were founded. One of the first to produce jeans in Japan was Big John, who in 1968 created a pair of jeans using imported Cone Mills fabric in Kojima. Domestic denim production was still developing but by 1972 Kurabo Mills had produced the first ever Japanese selvedge denim known as ‘Kurabo KD-8’. One year later in 1973, Big John presented the ‘M Series’ – using the KD-8 fabric – which became the first jeans that were 100% Japanese made. This included cotton which was locally grown and woven, with the jeans then cut and sewn in Kojima. This marked another turning point for Kojima and the start of the Japanese denim industry that we know today.

TCB factory. Photo courtesy of Koen Kuik.

TCB factory. Photo courtesy of Koen Kuik.

Kojima Today and the Japanese Denim Industry

Today, Kojima is a thriving and bustling area which is widely regarded as home to the Japanese denim industry, so much so that ‘Jeans Street’ was aptly named to reflect the area’s deep connection with denim. There are now over 200 denim related companies operating out of Kojima, with many moving there from other cities in Japan. The vast majority of Japanese denim is now woven in Kojima, with competition between brands, mills and wash houses pushing the quality of denim to new heights.

Enthusiasts and professionals now flock to Kojima in order to find the indigo expertise and high quality selvedge denim that the area has become known for – a far cry from the humble beginnings of the area that once struggled to feed its inhabitants. For us, Kojima is and always will be synonymous with Japanese denim. And we have a feeling that things are only just getting started. With technological enhancements and innovative brands looking to set the stage for the next era of Japanese denim, this is an area we’re going to keep a close watch on.

Kojima Jeans Street. Photo courtesy of Koen Kuik.

Kojima Jeans Street. Photo courtesy of Koen Kuik.

Share

Share

Tweet

Tweet