The Realign ‘Double Indigo’ Fabric From Warp to Weft

When we were browsing through the beautiful and authentic denim fabrics in the ‘Fabric Library’ of Collect Mills, in Kojima, Japan, and we saw the intense deep indigo blue shade, it caught our attention immediately. When we took a closer look at the color, the weight and quality, we knew that this could potentially be our next pair of jeans! We decided to produce a wearing sample, and after putting the jeans through a ‘field test’ for 12 months, we knew that our next pair of jeans needed to be executed in the 14 oz. ‘Double Indigo’ selvedge denim.

We just love the deep dark blue shades of the ‘Double Indigo’ fabric prior to wear, but the fabric will show its true beauty with time and wear as the fabric ages. Keep reading to find out more reasons as to why we chose this denim and the process behind its manufacture, how the fabric wears over time and for further details on the next Realign release.

How ‘Double Indigo’ is Made

The Double Indigo denim fabric is woven with yarns which are spun from a blend of 100% cotton from America and Australia. The yarns are made without elastane meaning that it is a non-stretch fabric. After the yarns are spun, they are rope-dyed in premium indigo, a method which is considered to be one of the best methods for dyeing yarns. During the dyeing process, the yarns are shortly and repeatedly dipped in indigo resulting in a dyed surface while the core remains undyed, as the short dyeing time does not allow the indigo dye to fully penetrate the yarns. Rope dyed yarns fade faster than yarns that are completely soaked with indigo and will show impressive high contrast fades over time and wear.

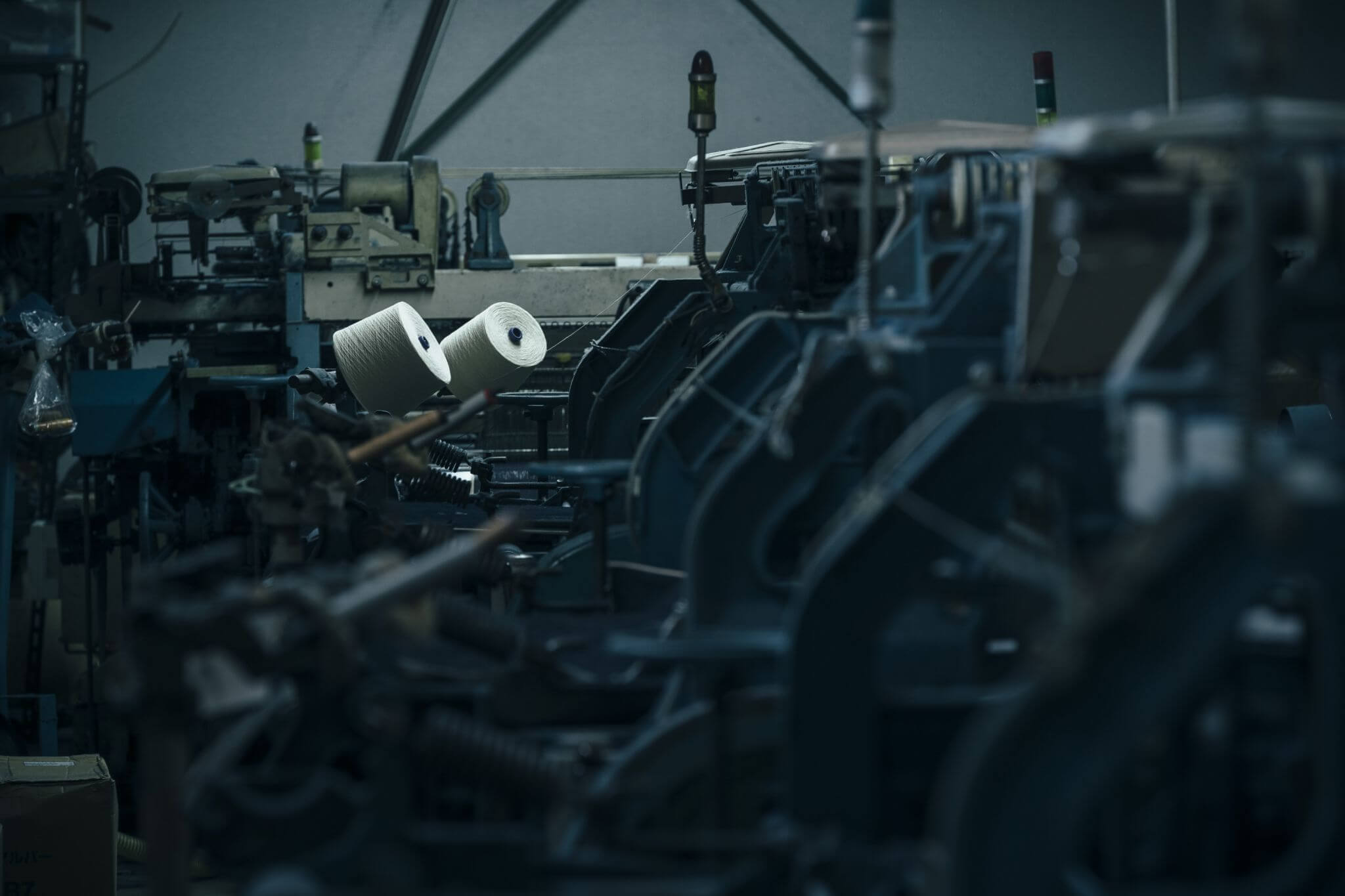

The rope-dyed yarns are then woven on antique shuttle looms – the traditional way of making denim – in a right-hand twill construction under a low tension. The low tension weave of the fabric makes the denim compact while breathable and stiff yet comfortable. Weaving on shuttle looms gives the fabric small imperfections and irregularities, for that true characterful and authentic Japanese ‘soul’, which can’t be produced on other looms. Something that also can’t be produced on ordinary looms is the high quality and longevity of the fabric – Authentic Japanese selvedge denim is true craftsmanship!

The 14 oz. Double Indigo fabric is unwashed and untreated in order to keep the fabric ‘raw’, but it has been sanforized in order to eliminate the majority of shrinkage. Due to the sanforization process the fabric may shrink around 3%, meaning that you can buy your actual or true waist size and an initial soak isn’t necessary.

Weight and Characteristics

The Double Indigo fabric is a made-to-order product of renowned denim makers Collect Mills and is woven in-house in Kojima, Okayama Prefecture. The name ‘Double Indigo’ derives from the composition of the fabric, which consists of indigo warp yarns and indigo weft yarns. This is a contrast to a more traditional denim fabric, which utilizes indigo warp yarns and white weft yarns. The ‘Indigo x Indigo’ composition is what makes the extraordinarily intense deep blue shade prior to wear.

Weighing in at 14 ounce per square yard (oz.), the fabric can be categorized as a mid-weight denim, making it feel comfortable yet sturdy from the very first wear. Due to its weight and composition, the fabric is suitable for wear year-round and an excellent choice for those who are ‘newer’ into the world of raw denim.

Fading Potential

The unique ‘double indigo’ fabric differs from the norm and gives extraordinarily intense deep blue shades, which is almost too beautiful to start wearing the jeans! But, you’ll be glad to know it gets even better with time and wear. The fabric may feel a little rigid during the first few weeks, but it will soon soften with wear, especially due to the weave and the weight of the fabric. The fabric will then begin to mold to your body shape, resulting in a clean and contemporary silhouette with a characterful aesthetic as the fabric fades.

With time and wear as the fabric ages, the fabric will start ‘fading’ which means that it will lose indigo on places where there is friction. The fabric will slowly start evolving, and due to the rope-dyed yarns, they will eventually show its white core resulting in high contrast fades.

If you’re looking to achieve high contrast fades, we would advise postponing the first wash for 6-12 months where possible. However, washing more frequently will achieve a ‘vintage’ aesthetic with a more uniform fade and colour throughout. Below you can see a sample of the denim which has been worn consistently for 12 months with one machine wash.

Head over to the Realign web store to learn more or purchase the RLGN-R 14 oz. Double Indigo.

Share

Share

Tweet

Tweet