Interview – Jens Olav Dankertsen, Founder Livid – Part 1

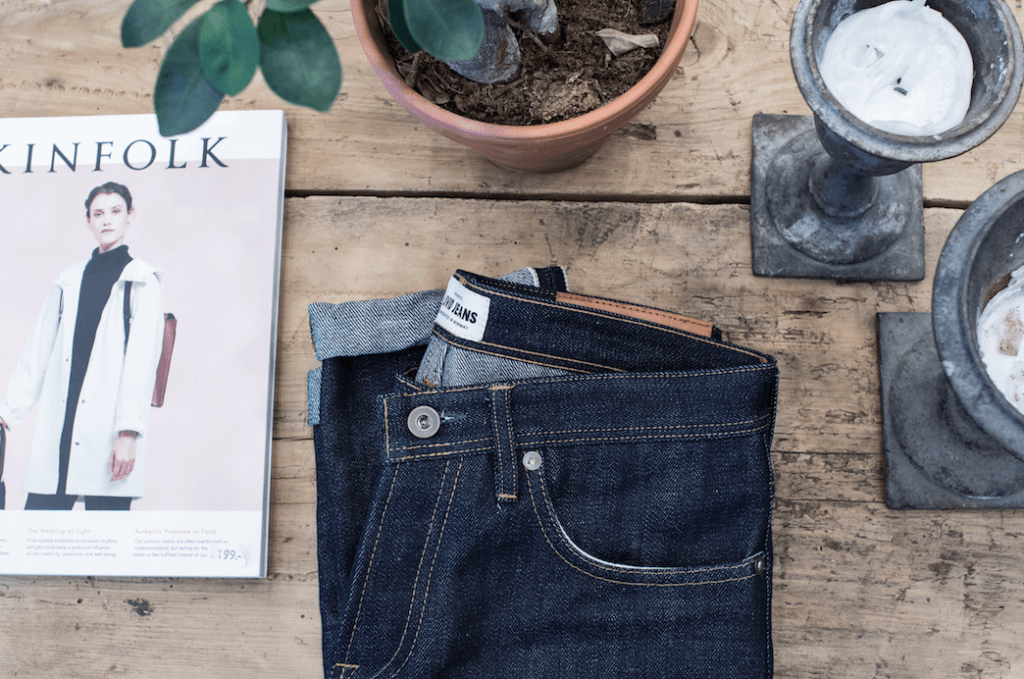

Livid is a Norwegian clothing label formed by a passion for fabric and construction. Their goal is to combine the Japanese finesse within fabric construction with the classic silhouettes of contemporary Scandinavian designs. Livid originated from a fabric and construction oriented perspective which means that the product determined the price instead of the other way around. Livid works with two different lines, namely; ‘Made in Norway’ & ‘Made in Portugal’. Both lines are made with the finest (Japanese) fabrics and constructed by artisans.

Recently, we spoke with Livid’s founder, Jens Olav Dankertsen about the history, the processes, the fabrics and the vision at Livid. During our conversation, we got hooked on Jens’ uncompromising vision on making garments. Jens took us along the history of Livid and explained the production process. When we asked Jens to describe Livid in three sentences he answered;

‘We are independent, self-made and uncompromising.

We are highly material- and production oriented.

We believe in being honest and transparent in everything we do.’

Today, in part one of our interview we will talk about the history and production processes at Livid. Jens will explain why he started Livid in the first place and will show us the steps taken in creating a new collection.

Robin Denim: Please introduce yourself.

Jens Olav Dankertsen: My name is Jens Olav Dankertsen and I am the owner and founder of the Norwegian clothing label Livid. I am 30 years old, have a degree in business economics and work today as a Managing Director and Designer at Livid.

Robin Denim: In what year was Livid founded? And by whom?

Jens Olav Dankertsen: The idea of starting a denim brand came early 2010, when me and three other colleagues of mine started dreaming about building our own company, and making jeans for a living. In May the same year, we established Junkie Jeans, which later on – when matured – became Livid. My friends decided early on to turn their heads over to different professions, while I was determined on keeping on running and building the Livid I had dreamt of. None of us had any prior experience in constructing patterns, making jeans or even running a company, so it was purely based on a huge interest in the field. Sure to say, it has been a bumpy but extremely exciting era.

Robin Denim: Since none of you had prior experience, you must have had some setbacks? Can you name a major setback(s) in the first years of Livid? And how did you deal with it?

Jens Olav Dankertsen: We’ve had tons of setbacks. But every challenge we have met, we’ve met with a curious and inexperienced mind. And fortunately, we have met them one by one. So even though some setbacks have been extremely challenging to tackle, we’ve always focused on the solution rather the problem. When you learn something as you go, it is tough, but you also tend to never forget the challenges you’ve met or how to avoid them in the future. Major setbacks for Livid have been big faults in production. This is always a struggle for small independent companies with organic growth. We do not have liquidity or reserves to easily help us solve losses like these. And future growth is all about the products we deliver to our customers. If they don’t hold up to our standards, we cannot put them on the market. So losses like these are really devastating for a small company like ours.

Robin Denim: Why did you start Livid? What where your original dreams?

Jens Olav Dankertsen: I never imagined that Livid would become such an important aspect of my life. Back in 2010, besides a fundamental interest in the world of denim, I think it was mostly based on making a specific kind of jeans supporting a specific kind of style. Back then, skinny jeans were arising, and while I; – style wise – swore to skinny jeans, that was obviously my first project at hand. It wasn’t until I actually began making jeans myself at the beginning of 2011, that everything kind of opened up to me. My dream took a very different path than what I first intended, and Livid became production-, construction- and material-oriented first, rather than anything else. Suddenly within eight months, I was sitting in my 12 square meter attic at home, surrounded by 6 big industrial sewing machines, constructing and sewing jeans every hour of every day after completing my regular work. I was obsessed on building my own jeans factory, and today it is the only manufacturing facility in all of Scandinavia with a day-to-day production of jeans.

Robin Denim: Where are the HQ located and where does the production take place?

Jens Olav Dankertsen: The Livid headquarters is located in a small town in the middle of Norway called Trondheim. With management, design, production as well as our retail store concept spread over three floors, everything here is happening under one roof. Our product portfolio includes two main production lines. Our ready-to-wear collection is made entirely in the northern region of Portugal, while our bespoke collection is made in-house in Trondheim, entirely without any third-party contractors. Having everything in one place really creates a dynamic atmosphere, and makes us able to create a culture that is deeply rooted in everything we do. Not only to the products we are making, but also to how they are being made, under which conditions and further on how we communicate those values to our customers.

Robin Denim: Can you describe the production process?

Jens Olav Dankertsen: New collections are always a very though process for me. Mostly I think it is because there is always so much to do, and so little time to do it in. And, being pressured on time and being creative doesn’t always go hand in hand. But, the process for us usually starts from a fabric oriented perspective and then implementing the main colours throughout the collection. This process starts at least 12 months before the collection actually hit the shelves in the shops. After colour and fabric selection, I normally determine styles, detailing and fit, construct patterns, spec-sheets and start the prototype process. After everything is decided, we order sample materials from their origin country to Portugal and the production of the sample collection is set in motion. Shortly after the tradeshow-season starts, where we show the collection to all of our clients and buyers from which we determine which styles and items that will go into production and our seasonal collection. Another 6 months ahead, the collection is finished in production and delivered to all of our retailers.

That’s the simplified version. The whole process itself has a lot of different aspects to it that needs careful attention both regards to its timetable, outcome of production and overall quality.

Robin Denim: What are your dreams / plans for the future?

Tomorrow, in the second part of conversation, we will dive deeper into Livid’s designs and fabrics. What is it that sets Livid apart? And why do they prefer to work with Japanese fabrics?

Share

Share

Tweet

Tweet