Interview – Jens Olav Dankertsen, Founder Livid – Part 2

Recently, we sat down with Jens Olav Dankertsen, the founder and owner of Livid. We spoke about the history, the processes, the fabrics and the vision at Livid. The first part of our interview, that we published yesterday, covered the beginning of Livid and Jens explained the production process and the time schedule for a new collection.

Today we dive deeper into Livid’s values, designs and fabrics. Jens will explain what sets Livid apart and why they prefer working with Japanese fabrics!

Robin Denim: How would you categorize Livid?

Jens Olav Dankertsen: As humans we always evolve, and so does our taste as well as our perspective on things. For us, we have been in a transition phase the last couple of seasons working on defining our aesthetics as a brand and our collections as a whole. We like to define ourselves as a more contemporary denim brand with a Japanese finesse. But, as I mentioned earlier we believe that, firstly, it is the ingredient and how it is made that defines the product. Secondly, we do not want to have any limits to what we make or where our place in the market is. If we want to make a jumper, we’re making a jumper.

Robin Denim: What makes Livid so special? What differentiates Livid from other brands?

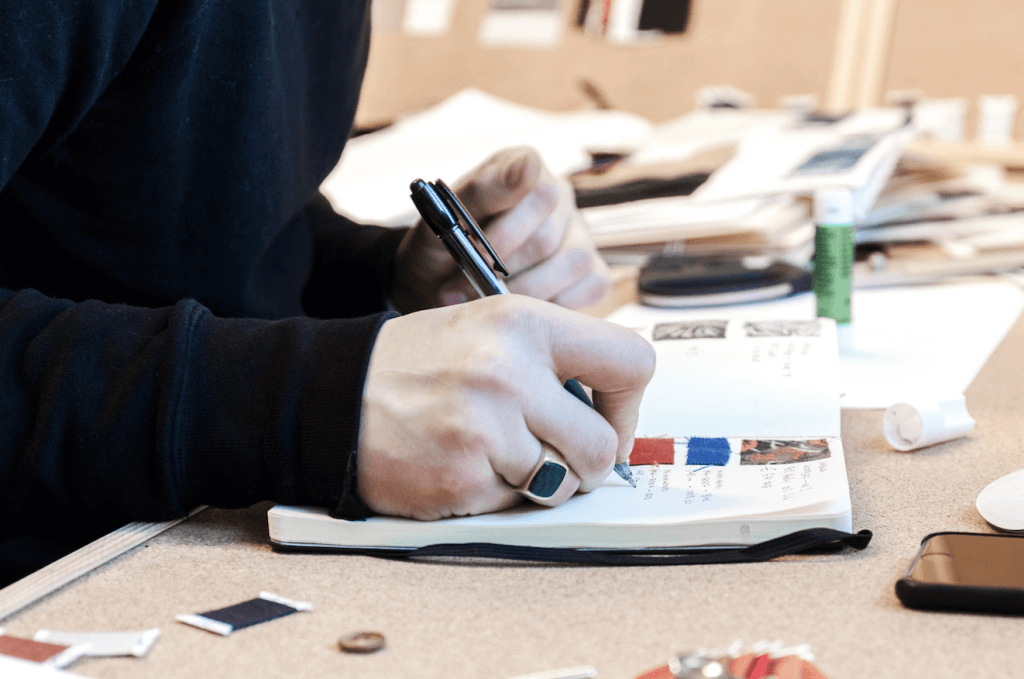

Jens Olav Dankertsen: I believe that what sets us apart from many others is that we are manufacturers and not designers, meaning that we actually produce products ourselves on a daily basis. We’re working in our own production facility every day, doing developments, testing constructions and always aiming to improve our status quo. In addition to that, we are material oriented and not price oriented. We always aim to make the best we can, the best way we can and at last, we put the price tag on.

Robin Denim: What are the most innovative items Livid has designed?

Jens Olav Dankertsen: That’s a difficult one. In terms of product, I do not think we are reinventing the wheel in any sense. No need to either, construction wise, there is way too much good stuff already from the old players. Not necessarily talking about Lee or Wrangler or even Levi’s. – But the really old players that were competing with Levis in the 1800s. While Levi’s had the patent of the rivet, the other companies really needed to be creative to come up with ways to compete and the detailing that came from that, is very inspiring.

But, in a market mainly driven by the competitive force of poor products made unsustainably, I believe in focusing on ways to produce our products more sustainably. We do not speak about quality only in the sense of the length of the fibre, or the quality of the dyestuff. We believe as much that a well-made garment has to be made by someone who makes a living making the garment. There are skilled sewers in Bangladesh, but did you know that the minimum wage is 7 times lower than what an average family needs to make a decent living, and 4 times lower than the national poverty line? A product made that way, is poor, doesn’t matter how long the cotton fibre is, – or if it has a self-edge or not. With that being said, there are good production facilities in those countries as well. But, that will be reflected in the end price.

With having our textiles made in Japan and our garments sewn in Portugal and Norway we have control over the conditions in which our garments are made. Regulated by strict governmental restrictions and national laws, which all of the production facilities needs to abide by, both in regards to human values as well as protecting our environment. In addition to this, we control our production facilities every season to make sure that this is followed.

With that being said, I believe information and transparency is crucial. Mass market will never change consumption as it is today, without understand the complexity of production. Textile production today, is not atomised. People make it. Even the jeans at $49, is made that way. And even we, who work with production every day, can’t understand how this is even possible. – Even with extreme quantities, because humans have limits to productivity.

This is obviously very important for us, and also something we have wanted to do something about for a very long time. Since June of last year, we have been working on opening up our value chain completely, making every step of the production transparent. Not only to the sewing of the product – which is only half of the process – but all the way down to the cotton farming.

Now, I am rambling a lot. Sorry. To try to get back to your question, I do think our approach to materials and how we decide to use them is different. Like making a conventional trucker in a non-conventional fabric. Or even a Norwegian-made five-pocket in an indigo dye 3×1 twill denim made of 60% silk / 40% cotton.

Robin Denim: How do you select your fabrics? Why only Japanese?

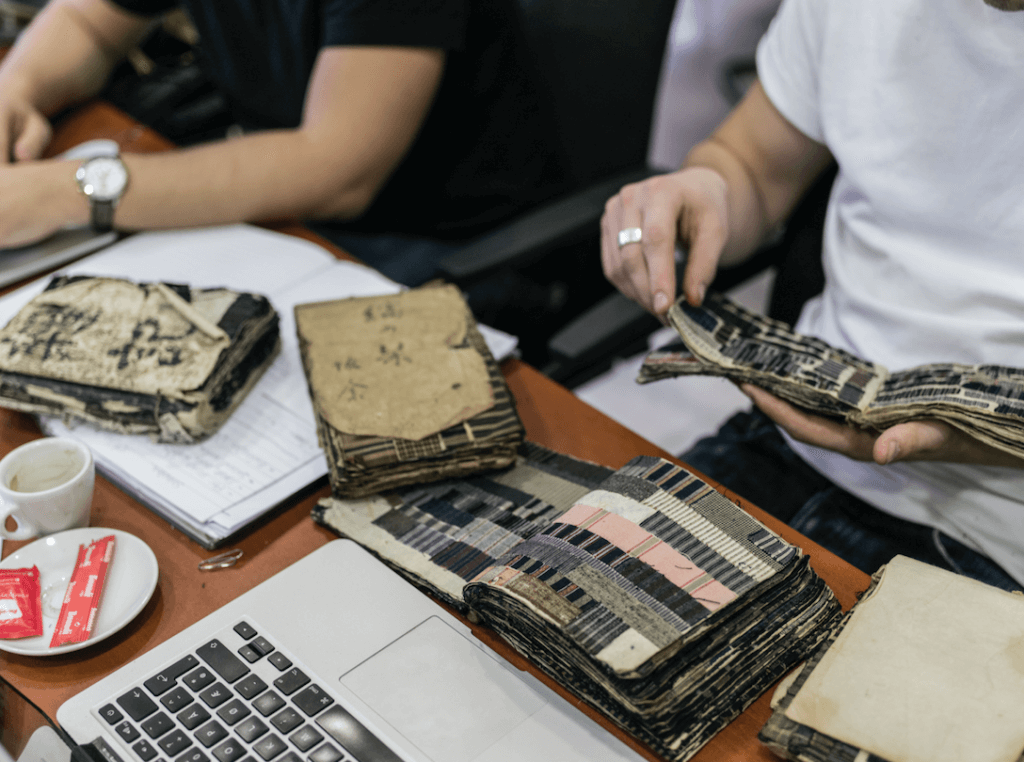

Jens Olav Dankertsen: Because they are the best at what they do. I believe that when the market changed its structure, textile makers, brands and producers started looking for cheaper ways to create products. With that kind of focus, you loose something on the way. I think the Japanese with their uncompromising focus on keeping their standard intact; they also kept hold of their traditions in making textiles.

In Portugal we also make custom developments like jerseys, prints and oxfords. And I remember a couple of years back we had a Japanese twill fabric with a cotton / hemp composition that we wanted our producers to have a look at. When their textile technician came in, he had a close and long look at the fabric through an eye loupe, and he looked up at us asking us if it was a Japanese fabric and we responded yes. And he simply replied; “Ok, because I do not understand what they’ve done here.”

It is as simple as, if you’ve only worked with premium fabrics, there is no turning back. – Because the majority of everything else feels mediocre.

Robin Denim: For your shirting fabrics, you work a lot with Nihon Mempu. Why did you chose to work with this specific mill? Do you Travel to Japan every season?

Jens Olav Dankertsen: Every season I choose to work with the mills that have the most exciting fabrics. If we end up using a lot of Nihon one season, it is because they simply have made a lot of great fabrics that season. So, season to season it tends to vary a lot. But, Nihon and Collect always have a lot of great fabrics in their collection. Also, Maruwa needs to be mentioned. They also do great lightweight narrow shuttleloom fabrics for shirting. I do my buying in Paris most of the time, but would love to do them in Japan sometime in the near future!

Robin Denim: What can we expect from Livid in the future when it comes to designs and fabrics?

Jens Olav Dankertsen: You can expect that we always challenge our aesthetics as a denim brand, and that we do not always stay within the barrier of how people perceive us. But, we will always hold true to the fundament of which we’ve grown from. Which is quality, sustainability, transparency, and knowledge first. Everything else is second.

Share

Share

Tweet

Tweet